Super Titanium™

Strong. Lightweight.

Gentle on the skin

What is the best material for a watch that is in direct contact with the skin all day, every day? As it was then being used in spacecraft, titanium was a material very much in the spotlight when CITIZEN unveiled the world's first-ever watch with a titanium case in 1970. Subsequently, through sustained research and development, we came up with what may just be an ideal watchmaking material. It's Super Titanium™, a proprietary CITIZEN material that is scratch resistant, lightweight, gentle on the skin and corrosion resistant too.

It's almost impossible not to scratch your watch as you go about your day. Super Titanium™ is created by treating titanium, a naturally soft metal, with CITIZEN's Duratect surface-hardening technology. Super Titanium™ has a surface hardness five times that of stainless steel, freeing you to live an active life, confident that your watch is safe from unwanted nicks and scratches.

Your watch is on your wrist all day, every day, so the

lighter it is, the better. Super Titanium™ is around half

the weight of stainless steel, making it comfortable to wear

even for extended periods.* Whether you're at

work, at home or out having fun, the sheer lightness of

Super Titanium™ will make your life easier and more

relaxing.

* Super TitaniumTM is 40% lighter than

stainless steel.

At CITIZEN, we want everyone without exception to enjoy

wearing a watch. Super Titanium™ protects against nickel and

metal allergies so it's perfect for people with metal

allergies, but it's also a boon for people with a partner or

family member who suffers from metal allergy.

* Not all Super Titanium™ models are

metal-allergy or nickel-allergy resistant.

Nothing spoils the look of a watch more than rust. Because Super Titanium™ is corrosion resistant, you can wear a Super Titanium™ watch with complete confidence in any situation you're likely to encounter in everyday life. Sweat resistant and resistant to discolouration, Super Titanium™ just keeps on looking good forever. * The pins in the bracelet may tarnish. Regular cleaning is recommended.

A CITIZEN-only material

Super Titanium™ is a proprietary material unique to CITIZEN. We make it by treating titanium with Duratect, our proprietary surface-hardening technology.

One-of-a-kind titanium-processing technologies

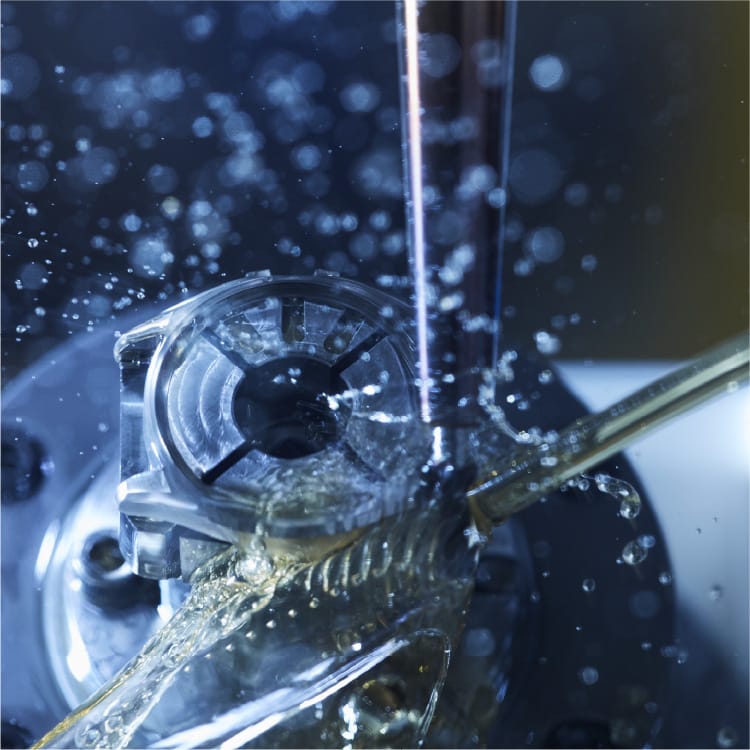

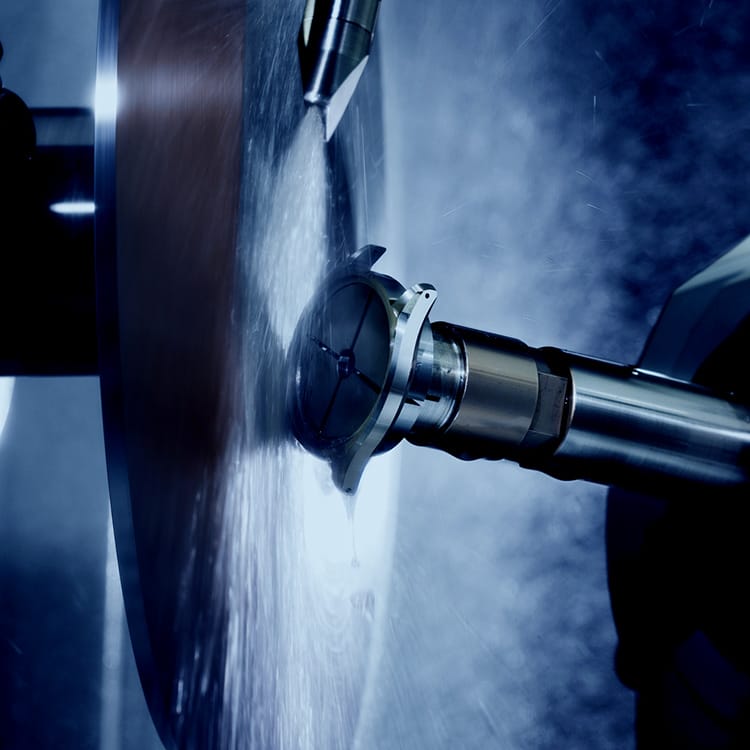

Titanium is very soft, a quality that makes it an extremely difficult metal to work with. In fact, turning titanium into a product that's perfect down to the last detail is a major challenge. Having spent decades researching titanium, CITIZEN has developed its own proprietary titanium-processing technologies. We only use carefully selected titanium materials that meet our demanding specifications and achieve beautiful finishes through pressing, machining and polishing processes that are unique to CITIZEN.

Cleaning technology for even higher quality

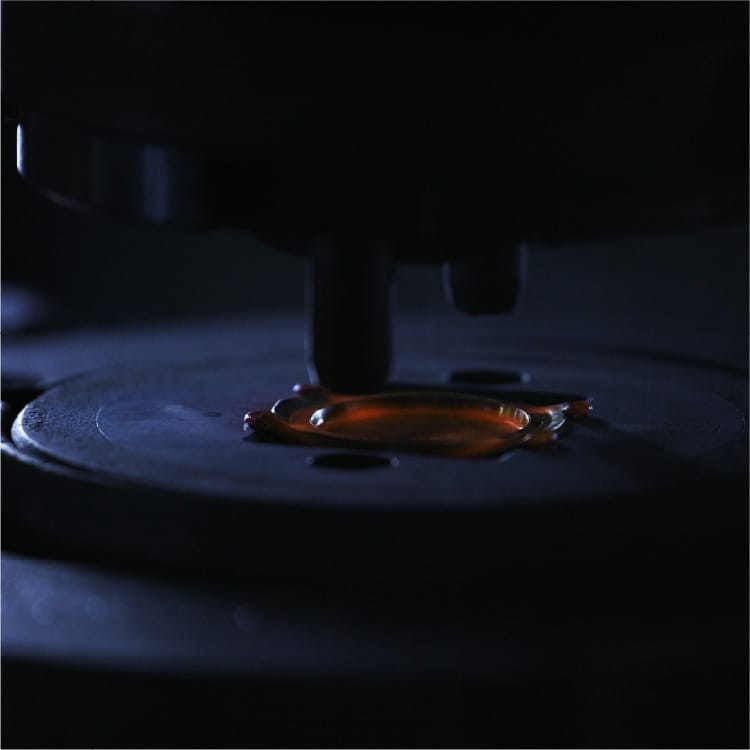

The next stage, which is an intermediate one, involves cleaning the titanium. A selection of cleaning fluids is used to remove lubricants and other impurities that have attached themselves to the watch during manufacturing. The extreme thoroughness of this cleaning process, which doesn't leave so much as a speck of dirt behind, ensures even better results when Duratect surface-hardening technology is applied at the next and final stage.

Duratect:

The final stage of the process

With the cleaning done, the time has come to transform the titanium into Super Titanium™ by treating it with Duratect, CITIZEN's proprietary surface-hardening technology. Duratect comes in three versions: one for coating materials; another for hardening materials' surfaces; and a third that does both. Selecting the version of Duratect best suited to the character of the watch makes it possible to control hardness and colour tone with a high level of precision.

The Super Titanium™ Story

Turning a space-age material into a watch

It's the 1960s. The eyes of the world are on the Apollo Program, the first manned mission to the moon. Due to its lightness, strength and corrosion-resistance, titanium is garnering attention as a material perfectly suited to use in space. Meanwhile, the engineers at CITIZEN are starting to realise that titanium might just be the ideal material for the watches that people wear in contact with their skin every day. It was this double insight that inspired CITIZEN to launch its research into titanium.

The world's first titanium watch

After a bout of intense research and development, CITIZEN released the X-8 Chronometer, the world's first titanium watch, in 1970, just one short year after Apollo had successfully landed on the moon. A combination of “X,” the letter that represents the unknown, and “8,” a number whose shape evokes the infinity symbol, the name suggests the infinite possibilities inherent in titanium, a then little-understood material.

Struggles with processing titanium

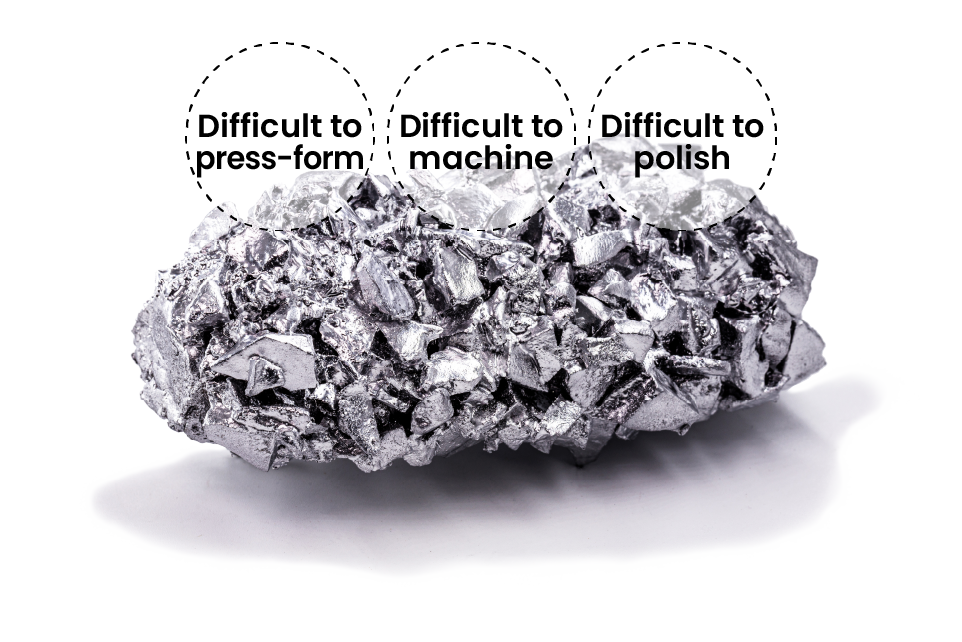

CITIZEN may have released the world's first titanium watch in 1970, but as far as we were concerned, the sheer difficulty of processing titanium meant that the whole project was still very much a work in progress. The CITIZEN engineers gave titanium the jokey nickname of “triple trouble,” because it was difficult to press-form, difficult to machine and difficult to polish. Because titanium is an extremely soft metal, the shavings often stuck to the cutting edges of tools, sometimes even catching fire, while no amount of polishing could bring it to a mirror finish. CITIZEN explored every possible avenue to solve these problems. After many twists and turns, we finally came up with a clutch of unique processing technologies no other watchmaker can match.

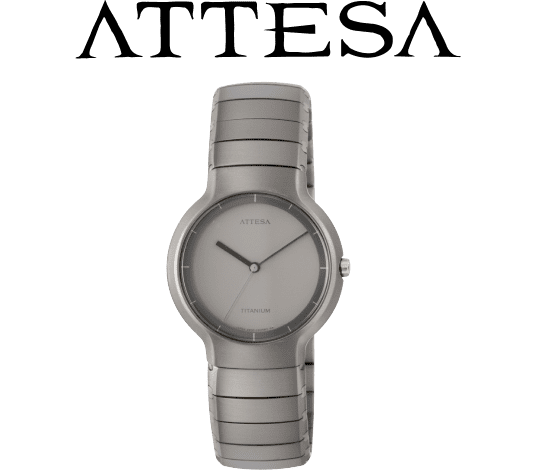

The debut of ATTESA

In the course of developing our processing technologies for titanium, we became aware of the metal's hypoallergenic properties. It took 17 long years of research and development, but our efforts to create a watch that was gentle on the skin culminated in this 1987 ATTESA model (sold only in Japan).

A watch for everyone

In the 1990s, we embarked on further research to understand titanium's hypoallergenic properties even more deeply. We teamed up with a group of dermatologists to conduct clinical trials of titanium watches on patients suffering from metal allergies. Through this collaboration with the medical profession, we successfully demonstrated titanium's hypoallergenic properties. We were one step closer to a world where everyone, metal allergy or not, could wear a watch in comfort.

Stronger. Tougher.

And even more elegant

Our quest for an ever-better version of titanium took a major step forwards in the form of Super Titanium™, titanium that has been treated with Duratect, CITIZEN's proprietary surface-hardening technology. The resulting watches were stronger, lighter, gentler on the skin; even more resistant to corrosion; even more elegant and attractive. As it came to be used in more CITIZEN models with a greater variety of designs, Super Titanium™ began to realise its promise.

Into the future.

And into space

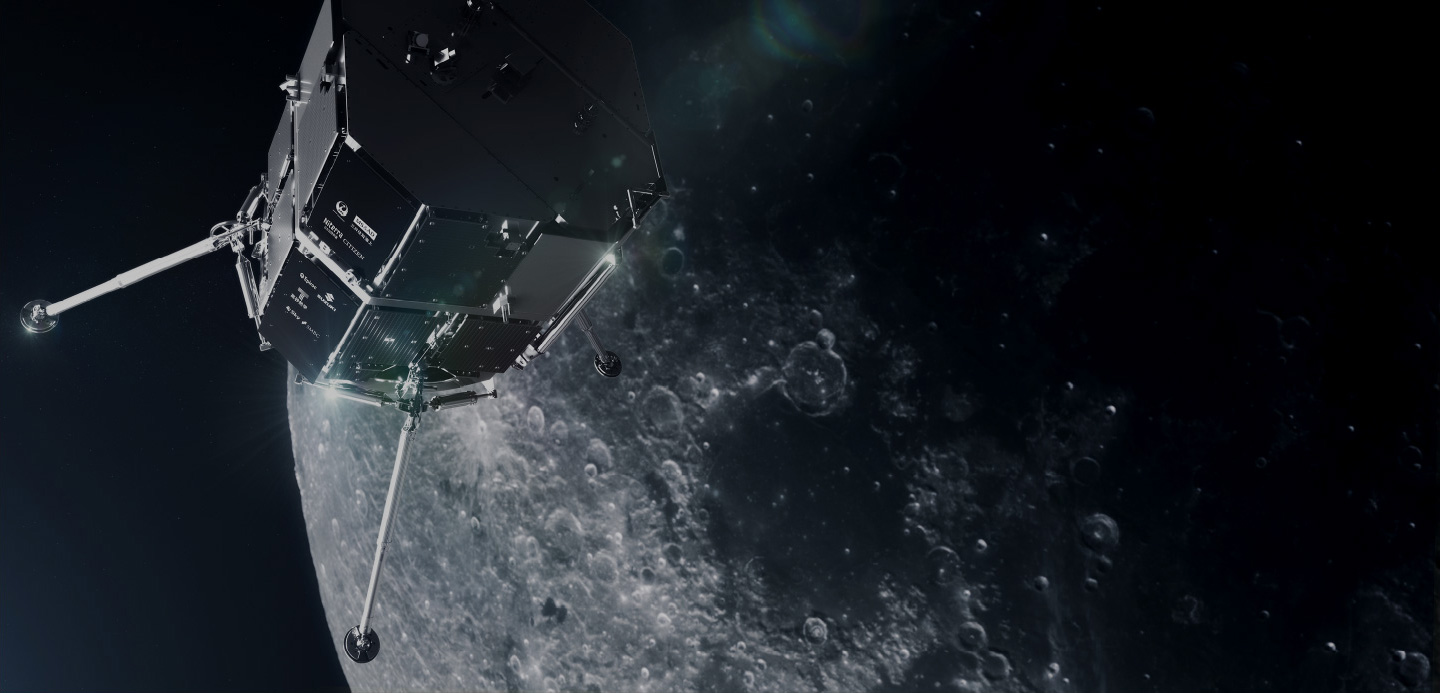

In 2019, CITIZEN became a corporate partner of HAKUTO-R, the

world's first commercial lunar exploration programme,

managed by the start-up ispace. CITIZEN provides Super

Titanium™ for the landing legs of the HAKUTO-R lunar lander.

The first HAKUTO-R mission gathered valuable data and

know-how from an attempted moon landing in 2023. Further

missions are currently in the preparation stage.

Having originally been inspired by the romance of space

travel, Super Titanium™ is once again returning to space.

CITIZEN will never stop exploring the possibilities of this

extraordinary material.

Some of the models introduced on this page are no longer in production or are Japan-only models.