TECHNOLOGYTechnology of

Caliber 0100

01

A quest for the perfectly

pure second

A light-powered watch that tells the world’s most precise time with accuracy of ±1 second per year.

Where does this level of precision come from?

The second hand of a watch counts out 31,536,000 seconds every year.

A watch with accuracy of ±1 second per year must mark those millions of seconds with annual deviation within just one second.

To mark the seconds with such perfect purity,

all the watch’s individual components need to be made with greater precision.

That is the challenge for near zero deviation.

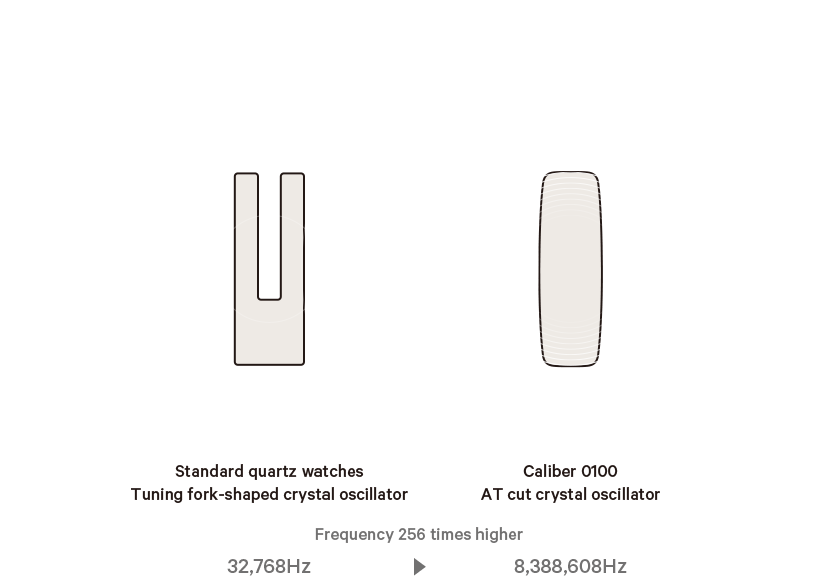

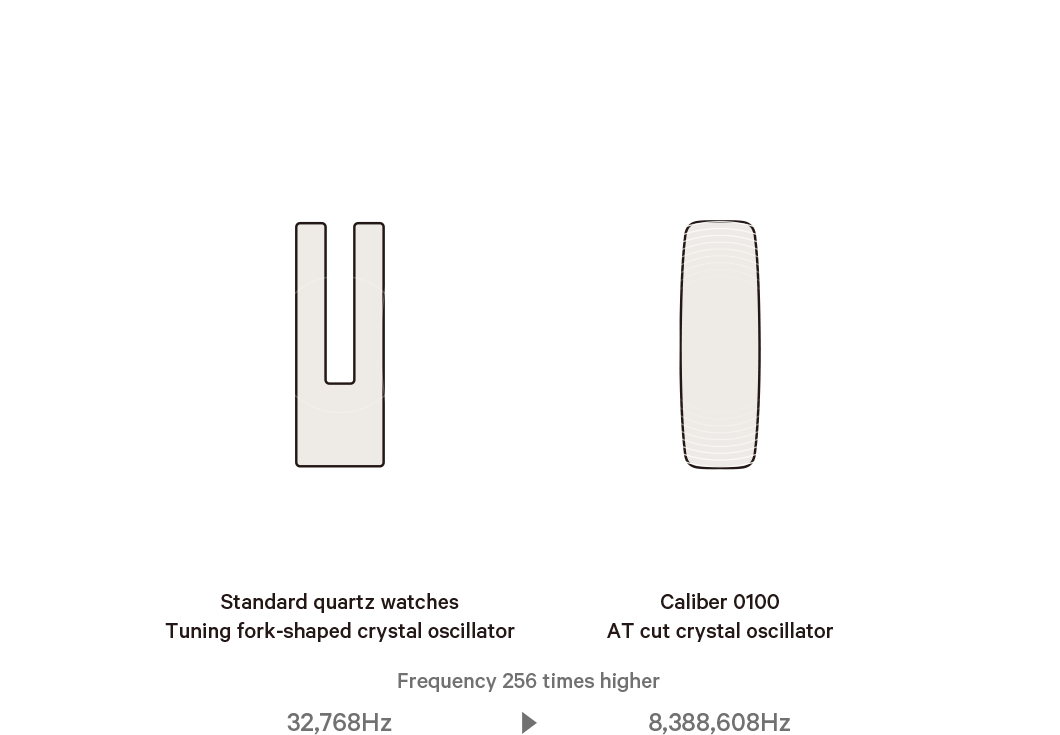

We elected to use an AT cut crystal oscillator in place of the tuning fork-shaped one used in most quartz watches.

We then focused on making the individual components—the hands, gears, motor, circuit, and so on—more precise.

Finally, by bringing in Eco-Drive light-powered technology, we created a watch that needs only light to keep telling the time with accuracy of ±1 second per year.

Created by CITIZEN’s advanced technologies,

the perfectly pure individual second takes shape,

resulting in perfect purity and precision.

AT CUT CRYSTAL OSCILLATORAvoiding deviations,

large and small

Quartz watches tell the time, second by individual second, by exploiting the way in which crystals oscillate at a fixed cycle. Although quartz watches are extremely precise compared to mechanical watches, small deviations can occur when external factors such as temperature and gravity cause changes in the frequency of the crystal oscillator. This level of deviation is hardly problematic for an ordinary quartz watch. When, however, the goal is accuracy of ±1 second per year, it represents a major deviation that cannot be ignored. We therefore decided to use an AT cut crystal oscillator which is resistant to temperature change and gravity.

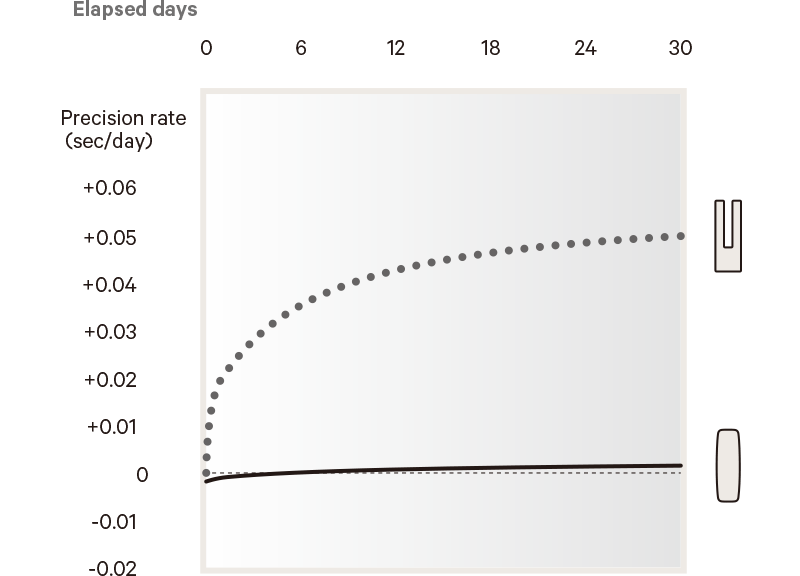

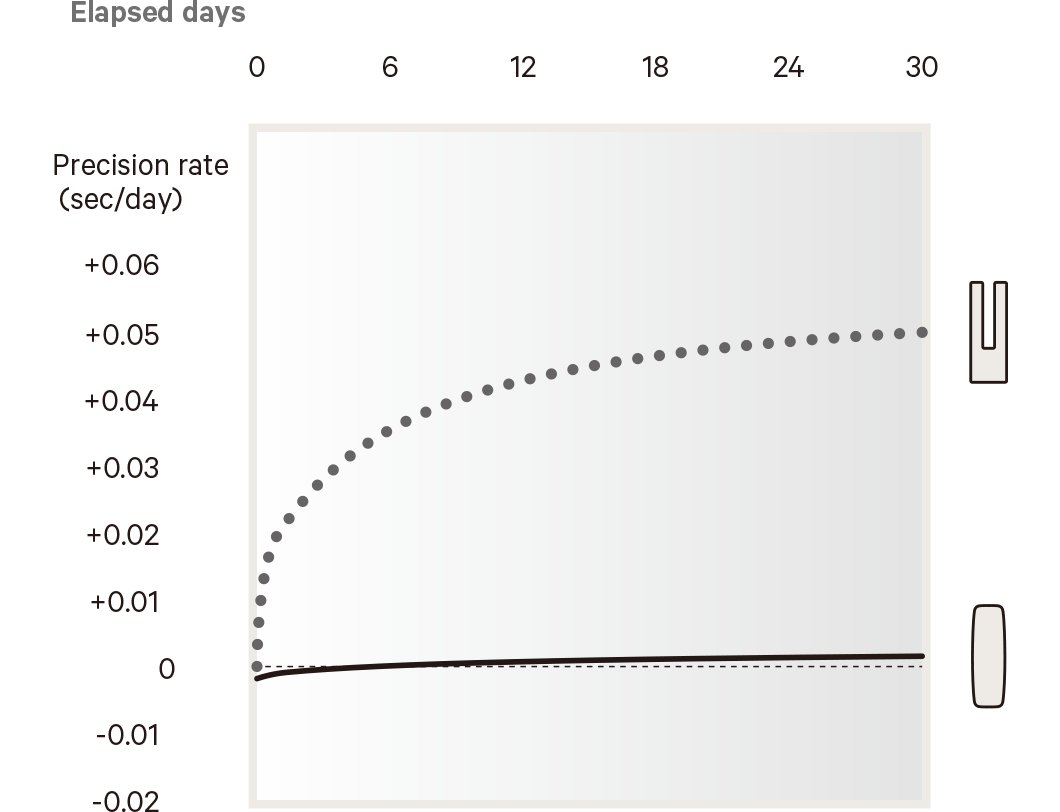

The AT cut crystal oscillator also has the merit of exhibiting a lower aging effect in its oscillation soon after completion than tuning fork-shaped crystal oscillators. As well as ensuring stability for our AT cut crystal oscillators through repeated aging, we even pretest their frequency as part of the manufacturing process, selecting only those that exhibit minimum change over time. We thus only use AT cut crystal oscillators with superior stability.

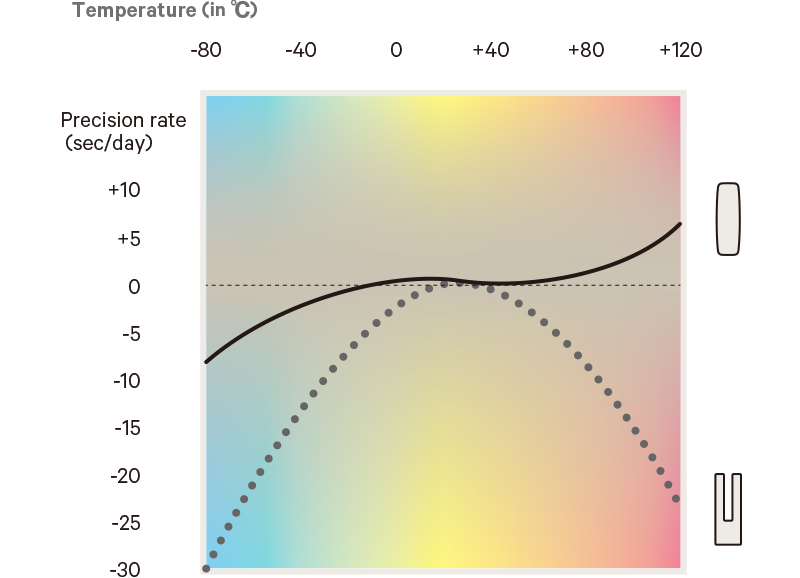

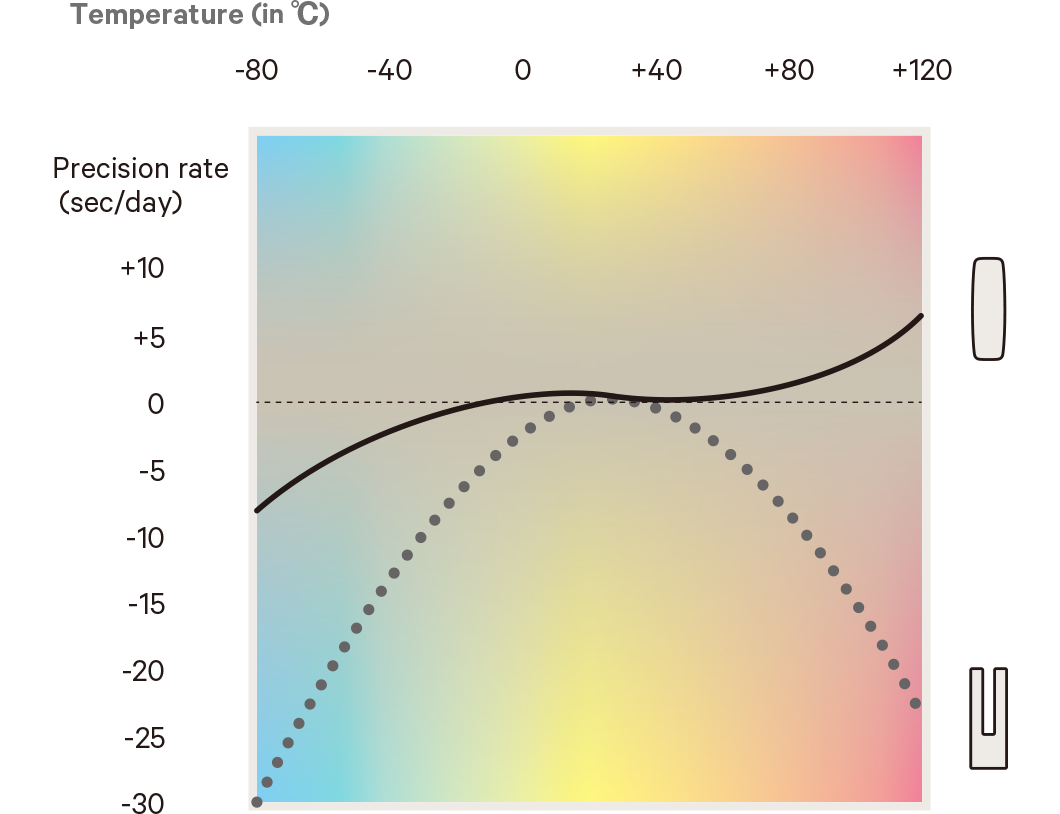

TEMPERATUREResistant to temperature change

To manufacture a crystal oscillator, you start by cutting it from a hexagonal source crystal. The angle of the cut determines the crystal oscillator’s thermal characteristics (i.e., frequency variability in response to temperature). As the diagram below shows, AT cut crystal oscillators have excellent thermal stability at normal temperature levels, something that keeps the impact of temperature change on them to a minimum.

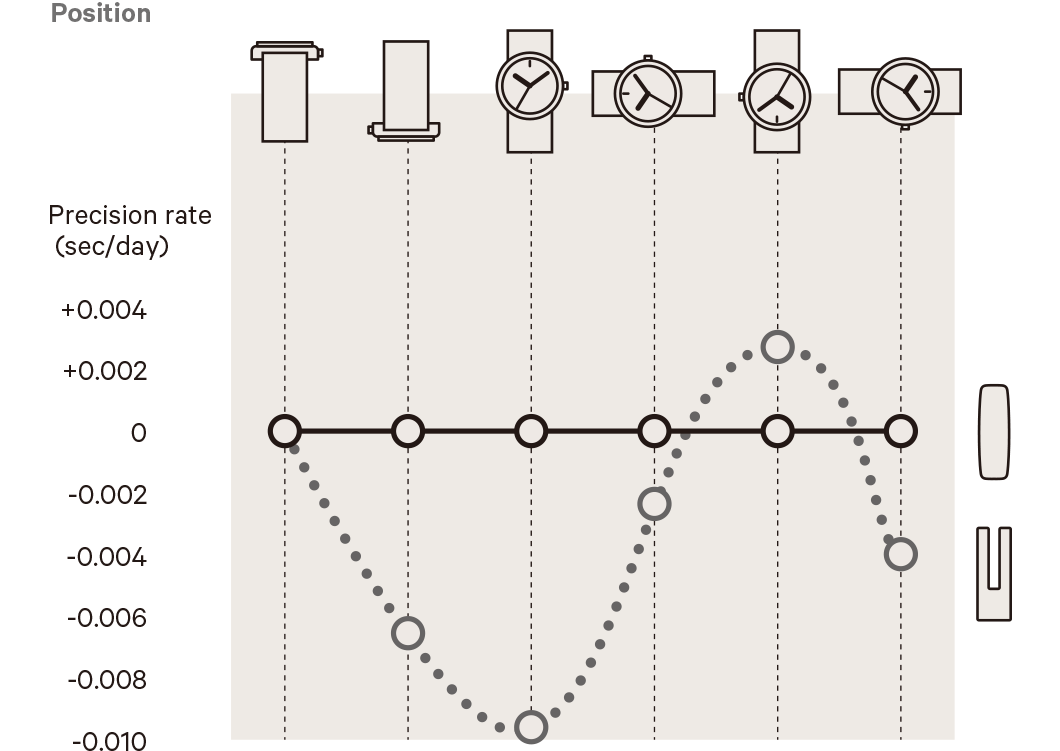

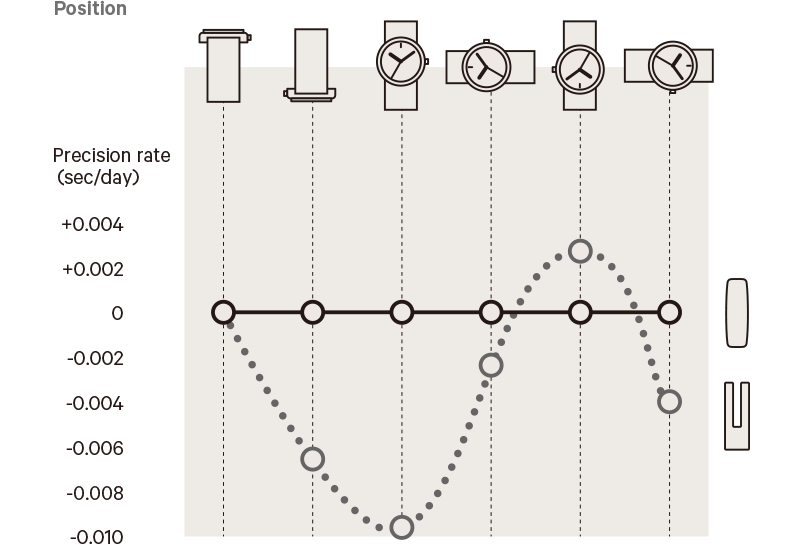

GRAVITYImpervious to gravity

Unlike clocks, watches end up in different orientations depending on the position of the wearer’s arm; they also experience different levels of gravitational acceleration from arm movements. Gravity has an impact on crystal oscillators. Because the standard tuning fork-shaped cut crystal oscillator has prongs that vibrate in empty space, changes in orientation can lead to minor deviations. By contrast, because of its shape, the AT cut crystal oscillator is more stable and less affected by changes in posture. It will keep marking the seconds with perfect precision whatever the orientation of the watch.