Next Level Quality

It’s not only about accuracy.

It’s the sensation, the feeling.

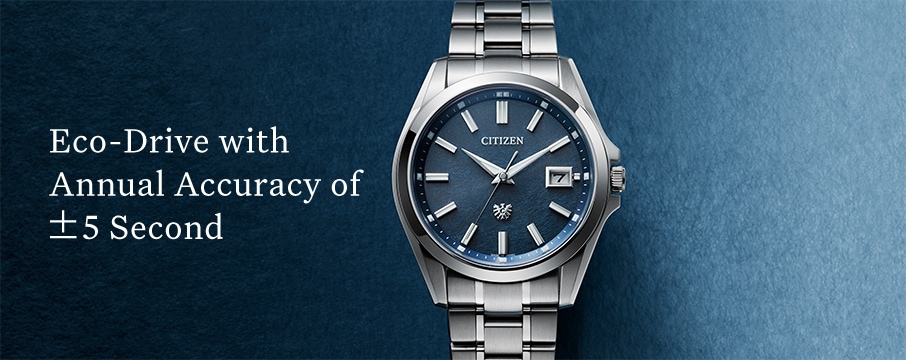

Developing Mechanical Models Caliber 0200/0210.

Citizen Watch Co., Ltd.

Citizen Watch has the full range of watchmaking capabilities in-house, from making individual components to final assembly. We distilled the philosophy, techniques and technologies that have been passed down inside the company since its founding to tackle the challenge of developing a new mechanical movement. The upshot was the Caliber 0200, followed by the Caliber 0210. What sort of ideas and enthusiasms drove the creation of the Mechanical Model Caliber 0200 and the Caliber 0210? We spoke to Kenji Tsuchiya, the engineer in charge of development.

Watch the movie

A commitment to accuracy and aesthetics

embodied in the very smallest details.

I want to start by asking about the Mechanical Model Caliber 0200. It has the first new mechanical movement CITIZEN has developed since 2010. What inspired the movement’s development?

CITIZEN has been making mechanical watches continuously since 1918, when the company was first founded. Electronic watches emerged in the 1960s and that was another technology we whole-heartedly embraced. As you know, we have a history of producing excellent products featuring Eco-Drive, our light-powered technology.

At the same time, there was a strong interest in making a high-end mechanical watch because of CITIZEN’s rich archive of mechanical watch models. With the development team all so keen, development got underway. The result was the Mechanical Model 0200, which came out in 2021.

At a personal level, did you have a clear idea of the kind of watch you wanted to make?

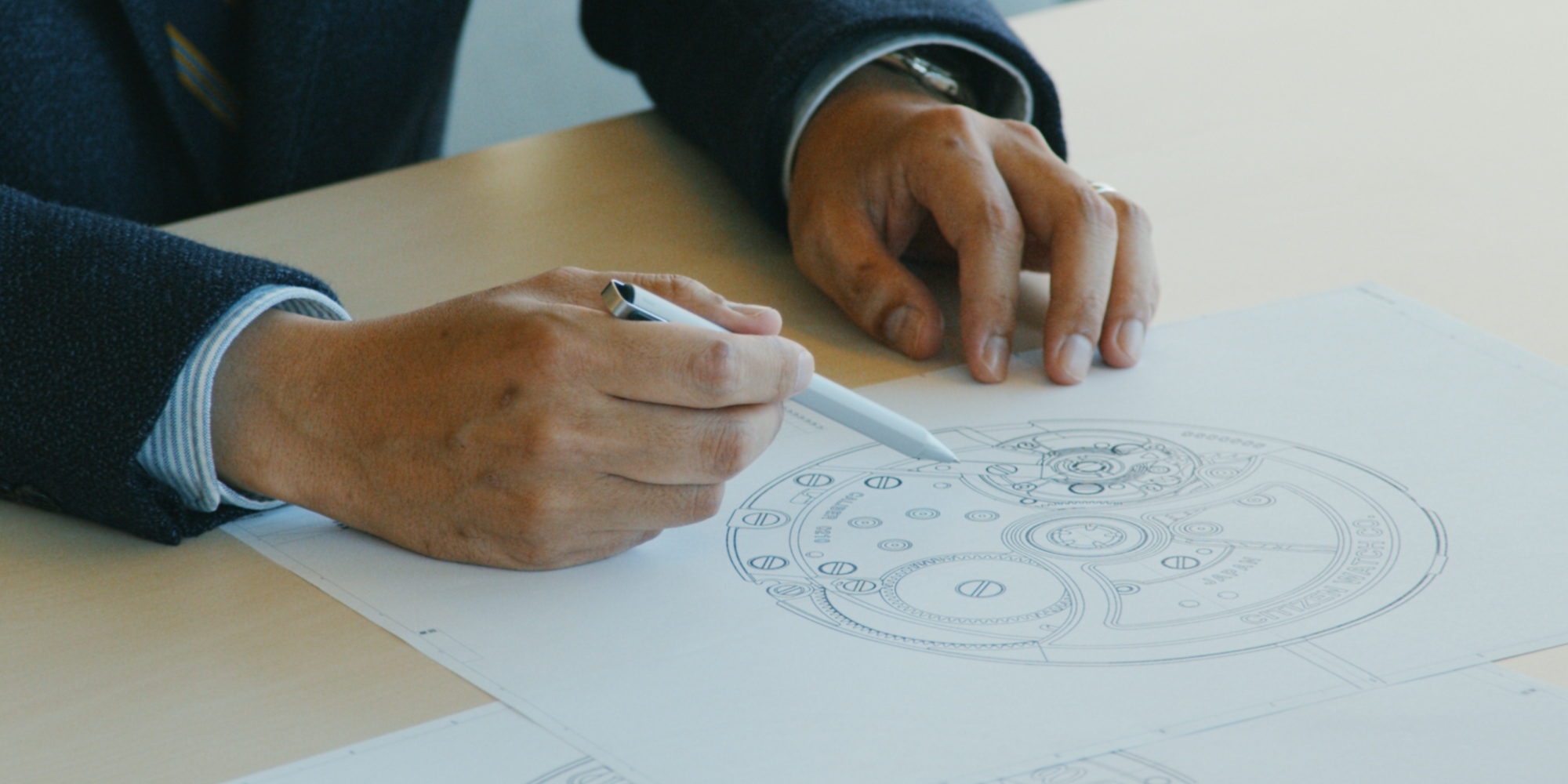

As I see it, the essential value of a mechanical watch lies in it condensing so much beauty and exquisite elaboration into something so small. There’s a special satisfaction you get from wearing it on your wrist. I wanted to create a product that would make people recognise intuitively just what a beautiful and worthwhile thing a mechanical watch is.

What themes drove the development process?

Ever since its origins, CITIZEN has always sought to craft parts of the very highest quality and then assemble those parts into highly accurate watches. Basically, that’s our company DNA. Since that was the basis for our development themes, accuracy was naturally enough the first major theme. We decided to target performance in excess of the ISO chronometer standard and use CITIZEN’s mastery of precise component-processing technologies to achieve it. In the end, we achieved daily deviation of -3 seconds to +5 seconds. One way we did this was by using a free-sprung balance for the balance wheel. The idea was to improve accurate time-keeping stability by eliminating the regulator.

I gather that elegance and aesthetics were another focus.

Definitely. An elegant aesthetic was the second major development theme. As a Japanese brand, we wanted to create a movement design that would fully embody Japanese precision manufacturing. What I’m talking about specifically are the bridges with their rectilinear hairline finishes and three straight line elements. Having these different straight lines as the design keynote evokes an image of meticulously crafted precision. We then gave the bridges diamond-cut bevels. The diamond cut creates strong, rectilinear reflections. It’s all designed to give the wearer the sense of an elaborate and precise product that’s been engineered to a very high level.

You thought a great deal about the placement of the gears within the movement.

We did. As part of the movement’s aesthetic, we wanted to explore the “fun” aspects that are unique to mechanical watches. The arrangement of gears is known as the gear train, and we laid out the gear train in the most elegant way possible. The elegant arrangement of the gears enabled us to make the movement into a really beautiful and coherent whole. That same thinking was also behind the placement of the small seconds at the 6 o’clock position.

Personally, I associate small seconds with more classical models. Why did you opt for a small-seconds dial?

I was just talking about the beauty of the gear train, but we learned something else in the course of making the movement. When you separate out the second hand into an independent small-seconds dial, you’re better able to focus on the movement of the second hand. At a visual level, it projects a strong sense of accuracy.

We sought to imbue the small-seconds hand with the same sense of precision and accuracy. In the movement design process, we decided on the coordinates for the small-seconds hand based on a layout that would maximise its visibility and elegant appearance. In designing the second hand, we were careful to ensure the hand was the right length to match the watch’s overall scale and was also easy to read.

The philosophy of the movement design

extends to the design of the watch exterior.

Does the watch’s exterior reflect the thinking behind the movement design?

The Caliber 0200 is a movement that’s all about the pursuit of accuracy, while the movement design is idiosyncratic and uniquely CITIZEN, so, yes, we wanted the watch’s exterior design to correspond with that worldview. In the Caliber 0200 development process, the exterior designers, the movement developers and the product planners had intense discussions and worked together closely to create a single coherent and unified product.

What are key elements in the Mechanical Model Caliber 0200’s exterior design?

We wanted the case design to send a message of accuracy and precision, so we opted to use what’s called a lugless case. That means you cannot see the lugs [the protrusions where the watch bracelet attaches to the case] from the front. Expressing “precision” by cleanly connecting one straight line to another resulted in a design that matches nicely with the taste of the movement itself.

Has CITIZEN used lugless cases in the past?

CITIZEN made enthusiastic use of lugless cases in the 1960s, when it was first coming out with its trail-blazing electric watches. Of course, we had no interest in simply reviving or repeating an old model this time. We made multiple improvements in all the key parts to give the watch a more contemporary look.

I know you paid a great deal of attention to the exterior detailing.

Absolutely. How can we optimise the space between the glass and the dial, the hands and the dial, the movement and the glass case back? What size of case back glass will show off the movement to optimum advantage? The exterior design team and the movement team made collaborative decisions on all these things. One episode that made me happy was hearing the exterior design team leader ask the movement design team leader what kind of design he had in mind for the watch. Obviously, as craftsmen, they each have their pride, but their shared desire to create something really good unleashed synergies and had a multiplier effect. The result was an even better model.

Moving on to the Caliber 0210:

More practical, with no loss of comfort.

About two years after the Mechanical Model Caliber 0200, the Caliber 0210—which adds a date function—came out.

With the Caliber 0210, we were determined to retain the same level of excellence of the Caliber 0200. While it retains the same accuracy and elegant aesthetic, we updated it with more practical features, adding the date window and 10 BAR water resistance to serve a diversity of customer needs.

How did you organise the development process?

Since we were going to add a date function, the process we followed was this: first the designer calculated the optimum size for the date window and then we built that into the design of the movement. The Caliber 0210 is a movement made exclusively for the mechanical models of The CITIZEN brand. The size of date window that the designer deemed to be ideal for the finished product was straightforwardly reflected in the movement design. That’s quite unusual.

What were the big issues you confronted when adding the date function?

Adding a date window means that you are adding a calendar mechanism. Adding something new necessarily results in an increase in thickness and a drop-off in comfort. To stop the movement becoming thick and uncomfortable, we hollowed out the base plate so we could fit components into it, then by cleverly balancing out the bulkier parts with the gouged-out parts, we managed to restrict the overall change in thickness to just 0.3mm.

What is the highlight of the Caliber 0210 for you?

What I am going to talk about is common to both the Caliber 0210 and the Caliber 0200. One place we were quite obsessive about is the design of the bracelet join. If you look at the watch, you’ll see that there is a single mirror-polished surface acting as the borderline between the bracelet and case. The bracelet design has a sense of unity, but the addition of that single mirror-finish surface really shows off the shape of the watch’s body—the combined case, bezel and dial—to maximum advantage.

The watch crown is an expression of our

twin strengths in design and manufacturing.

What did you take most seriously in developing a mechanical watch?

With mechanical watches, one area that is crucial is physical sensation, tactile feedback. That’s particularly true of how the watch feels when you are operating it. We want our customers to get physical pleasure from operating the watch. We did repeated prototyping to make sure that when you pull out the crown [the button for adjusting the date and the time] or wind the watch you get satisfying haptic feedback. We wanted the design to be as comfortable and as easy to operate as possible.

In other words, things like the “finger feel” when you wind the watch—things that are hard to measure or express in numbers—are really important.

Yes, a mechanical watch is all about sensation and feeling. Getting those nice tactile sensations comes down to the design of the gears and the precision of their machining. It’s something you can only achieve when your precision design and precision manufacturing are harmoniously intermeshed. When people operate the watch—pull out the crown and then winding it—they will feel through touch the strengths in design and in manufacturing that CITIZEN enjoys as an integrated watchmaker.

What’s the outlook is for further mechanical models?

Developing movements that keep more accurate time and have more beautiful finishes are both things that enhance our capabilities as a company. I hope we can apply these enhanced capabilities to future models. We are keen to transmit the skills and know-how of high-end watchmaking to the next generation, so we can keep making fantastic mechanical watches in Japan. Accuracy and aesthetics are the twin development themes we’ll focus on, going forwards.

This is my final question. Can you give us a message for people who are thinking of buying the Caliber 0200 or 0210 mechanical models?

The unique-to-CITIZEN movement design, the gear layout, the decoration and finishing of even the smallest parts, the way the watch’s exterior design expresses the same sense of precision—the list of things we lavished care on is literally endless! It’s because we refused to make any compromises that the Caliber 0200 and 0210 are such excellent products. I really hope people will try on the watches to get a proper sense of what makes them so special.

About

The hand that makes the washi for the dial…

The hand that inspects the materials…

The hand that sketches the design…

The hand that assembles the watch…

Aspiring to be an integral part of your life.

In the pursuit of the next ideal in timekeeping,

The CITIZEN has a passion for making beautiful things.

The living embodiment of superior craftsmanship,

Our watches pass through a succession of skilled hands

Before reaching their ultimate destination:

the wrists of the wearers.

In Hand to Hand Story,

We highlight all the expert hands,

So dexterous, sensitive and thoughtful,

Required for the complex process of watchmaking.