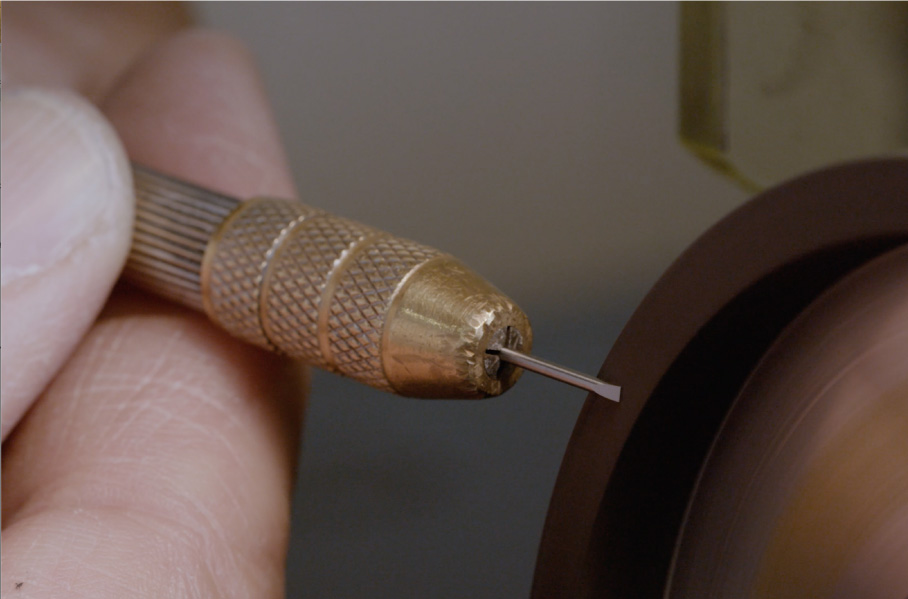

Every part, however small,

is CITIZEN-made.

A watch is the result of assembling hundreds of mind-bogglingly small parts. Some finer than a single strand of human hair. Some so tiny they can only be seen with a microscope. Screws, gears, springs, coils, motors. The hairsprings in our mechanical watches. At CITIZEN we make every part of our watches ourselves, no matter how small or complex.

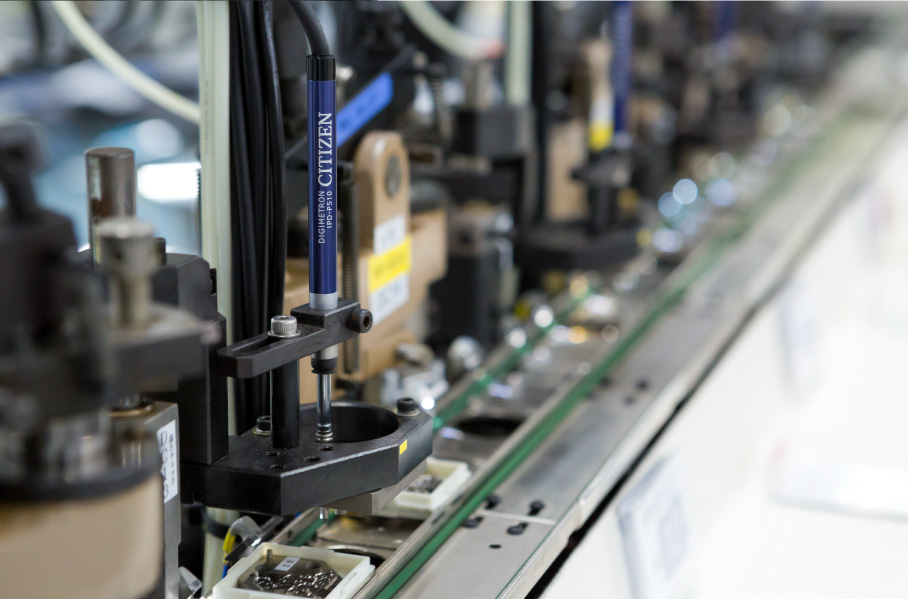

And we make the machines

that make the parts.

Watch parts have not only got to be highly precise, they're often complex in shape. They can't be produced using standard machinery. That's why at CITIZEN we custom-make the machines that make the parts and sometimes even blend the oil that keeps the machines running smoothly. In our factories, machines emblazoned with the CITIZEN logo are hard at work every day.

Devoted to developing dials

that absorb light.

Making beautiful watches is part of the CITIZEN mission. With models that feature Eco-Drive, our light-powered technology, we take care to place the solar cells under the dial or on its outer edge, where they cannot be seen. This makes for a handsomer-looking watch, but it also requires special know-how. That is why CITIZEN always makes its own dials: gorgeous dials that are translucent but never transparent. That too is something we can do because we are a manufacture.

The quest for a one-of-a-kind

crystal oscillator.

At CITIZEN, we even make the crystal oscillators for our quartz watches in-house. People tend to be impressed by the exteriors of our best watches. In fact, though, a lot of their appeal can be explained by what's going on inside them.

In 2019, CITIZEN released the Caliber 0100, a watch with annual accuracy of ± 1 second, a record for a wearable autonomous timepiece. A lot went into achieving that extraordinary level of accuracy: careful selection of the crystal materials used for the movement's crystal oscillator; a different cut for the crystal; improved efficiency of the integrated circuit. We developed all the technology ourselves. To produce an ultra-accurate autonomous watch in an era when smartphones provide instant access to the precise time is something that only a true manufacture would dream of doing. You need engineers, scientists and watchmakers who combine tenacity with a passion for watchmaking. You need to be… CITIZEN.

The significance of doing

everything ourselves.

Why are we so committed to making everything in-house? The answer is because that's the only way we can produce the watches that we want to produce. It's because we're obsessive about detail, fanatical about precision, and because we manufacture and assemble everything ourselves that we can turn our dreams into reality. As we do all our own R&D and testing too, the whole process can become challenging and time-consuming. But that is what makes CITIZEN a manufacture, an integrated fabricator that makes all the parts that go into its watches.